Continuous Contact Coding Printing Solution

Competitive Prices | Nationwide Delivery | Installation | Responsive Support

Semi-automatic or continuous contact marking printing technologies allow the marking of non-variable information on all types of media in a simple, easy, and economical manner in the production line. Continuous contact marking printing technologies can be easily integrated into your production line and guarantee consistent quality marking for your products.

Range of Continuous Contact Coders

View the range of continuous contact coders we distribute, install and support. Get in touch with us for more information.

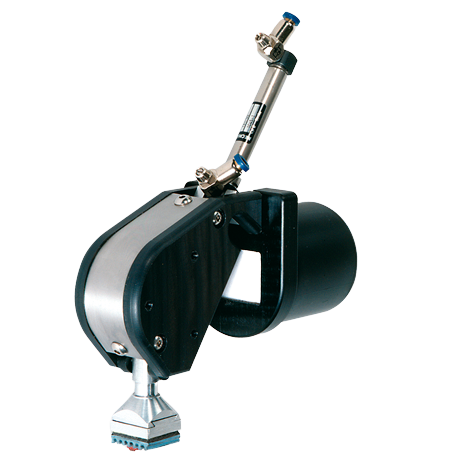

TC pneumatic reciprocating coder

Simple and robust, the TC pneumatic encoders allow marking on all types of suuports.

More Details

They will provide you with precision marking thanks to precise settings of the object contact and the ink contact.

Performance and speed

Up to 150 prints per minute.

Pneumatic or electric trigger.

Marking on top, bottom or side.

Also works in manual workbench station from below.

Applications

Texts, coding, dating, graphics, logos and part identification.

For porous and non-porous substrates.

Target markets

Food processing, automotive industry, packaging.

Key points

- Small footprint for better integration.

- Quick and easy change of characters and snapshots Autoclips.

- Secure cartridge system (avoids ink drying and evaporation).

- Interchangeable composter very quickly to prepare future markings in advance.

- Economical and reliable solution.

- Automatic or semi-automatic version.

Rollerflex Flexographic Coder

Flexographic printing unit for continuous marking on various materials.

More Details

Performance and speed

Up to 250 m/min. Marking on top, bottom or vertical.

Works with individual cartridge or electronic ink dispenser.

Applications

Texts, coding, graphics and logos. For porous and non-porous substrates.

Target markets

Industry (metallurgy, textiles, packaging, wood, extrusion…).

Key points

- Easy integration.

- Quick and easy change of characters and snapshots Autoclips.

- Secure cartridge system (avoids ink drying and evaporation).

- Easy to dismantle for cleaning.

- Economical and reliable solution.

- Adaptable with photopolymer plates.

- Wide range of inks available.

Rollerprint Rotative Coder

The Rollerprint is a flexographic marker designed for continuous marking on various materials.

More Details

Performance and speed

Up to 100 m/min. Marking on top, underneath. Works with individual cartridges.

Applications

Texts, coding, graphics, and logos. Continuous or dashed lines, reel end marking. For porous and non-porous substrates.

Target markets

Industry (metallurgy, textiles, packaging, wood, extrusion…).

Key points

- Easy integration.

- Quick and easy change of characters and snapshots Autoclips.

- Economical and reliable solution.

- Wide range of inks available.

- Available in manual version (SMAC).

Rollerpack Rotative Coder

The Rollerpack is a rotary marker, it is mainly intended for the marking of cardboard boxes on conveyors.

More Details

Performance and speed

Up to 25m/min.

Marking on the side, above or below.

Works with plastic-inks roller.

Applications

Texts, coding, graphics and logos.

For porous substrates.

Target markets

Industry (packaging, wood).

Key points

- Easy integration.

- Quick and easy change of characters and snapshots Autoclips.

- Economical and reliable solution.

- Indexed or continuous marking.

- Available in tape version.

Request More Information

We are a major distributor of printing and marking solution products in Nigeria. Fill out the short form below to get a free quote or request more information.

We are a one-stop shop, and a leading innovative, technology-driven and service-oriented source for wide-ranging varieties of equipment, machinery, spare parts, and technical support services/solutions for industries and homes.

Air curtains & Purifiers

INDUSTRIAL PRINTING & MARKRING

Water Treatment & Filtration

Air handling units & Ventilation

Packaging & End of Line Systems

PRIVACY POLICY | TERMS AND CONDITIONS | COOKIES POLICY

© 2023 Ozed Ventures Limited. All Rights Reserved. OZED is Nigeria Registered Co.